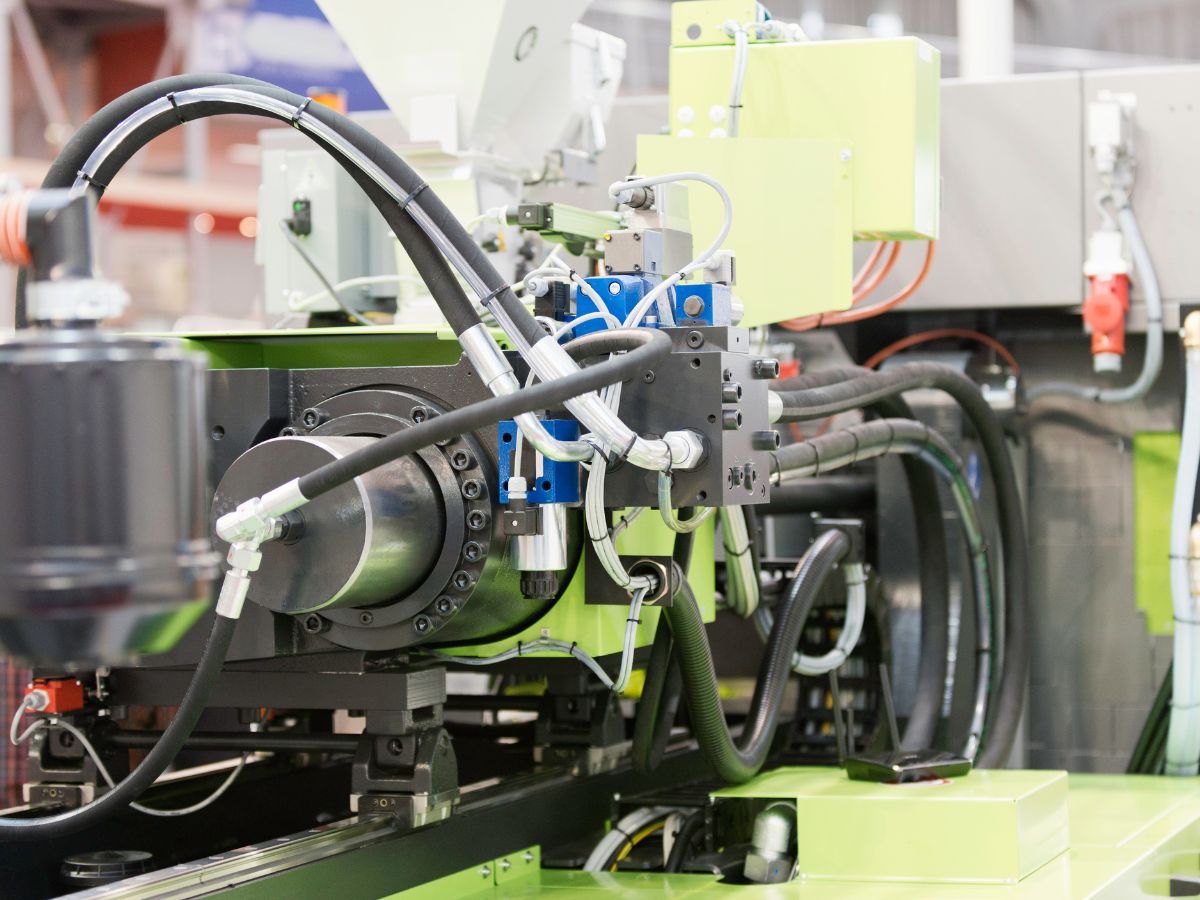

Injection Molding Machine: The Backbone of Modern Plastic Manufacturing

The injection molding machine has become the foundation of plastic product manufacturing in industries worldwide. From automotive components to consumer goods and medical devices, this machine ensures high precision, mass production capability, and cost efficiency. As demand for plastic products continues to grow in 2025, businesses increasingly rely on advanced injection molding systems for scalable, sustainable, and reliable production.

What is an Injection Molding Machine?

An injection molding machine is an industrial device designed to manufacture plastic products by injecting molten plastic material into a mold cavity under high pressure. Once cooled, the mold opens, and the finished product is ejected.

Core Functions:

- Melts raw plastic material (pellets or granules).

- Injects molten plastic into a mold.

- Applies pressure for shaping.

- Cools and ejects the molded part.

Main Parts of an Injection Molding Machine

| Part | Function |

|---|---|

| Hopper | Feeds raw plastic pellets into the machine. |

| Heater/Barrel | Melts the plastic material uniformly. |

| Screw | Moves and compresses the molten material. |

| Clamping Unit | Holds the mold firmly during injection. |

| Injection Unit | Forces the melted plastic into the mold cavity. |

| Cooling System | Solidifies the product for ejection. |

| Ejector System | Removes the final molded product. |

Advantages of Injection Molding

- High Efficiency – Large volumes of products can be produced in short cycles.

- Precision and Accuracy – Maintains consistent dimensions across thousands of units.

- Material Versatility – Compatible with a wide range of thermoplastics and thermosetting polymers.

- Reduced Waste – Leftover material can often be reused.

- Scalability – Suitable for small runs as well as mass production.

Applications Across Industries

- Automotive: Dashboards, bumpers, interior trims, connectors.

- Medical: Syringes, surgical tools, diagnostic components.

- Consumer Goods: Toys, packaging containers, electronics housings.

- Construction: Pipes, fittings, insulation parts.

- Electronics: Housings for devices, switches, connectors.

Types of Injection Molding Machines

- Hydraulic Injection Molding Machines – Traditional, powerful, and cost-effective.

- Electric Injection Molding Machines – High precision, low energy use, and quiet operation.

- Hybrid Injection Molding Machines – Combines the strengths of hydraulic and electric systems.

- Servo Injection Molding Machines – Uses servo motors for enhanced efficiency and precision.

Key Factors When Choosing an Injection Molding Machine

- Clamping Force – Determines the size of mold it can handle.

- Shot Size – Amount of molten plastic that can be injected in one cycle.

- Cycle Time – Speed of operation impacts production output.

- Energy Efficiency – Lower power consumption reduces costs.

- Automation Compatibility – Integration with robotics for smart manufacturing.

The Role of Daoben Machinery

A reliable manufacturer plays a critical role in ensuring long-term production success. Daoben Machinery is one of the trusted global suppliers of injection molding machines, known for innovation, durability, and precision engineering.

Why Choose Daoben?

- Advanced technology with servo and hybrid systems.

- Machines designed for energy savings and sustainable production.

- Wide product range covering automotive, packaging, electronics, and more.

- Strong technical support and after-sales service.

- Global presence with trusted customer base.

Trends in Injection Molding Technology (2025)

- Smart Factories – Integration of AI and IoT for predictive maintenance.

- Sustainable Plastics – Increased use of biodegradable and recycled materials.

- Micro-Molding – Precision production for medical and electronic components.

- Energy Optimization – Machines designed to minimize power usage.

- Robotic Automation – Seamless part handling and assembly during production.

Conclusion

The injection molding machine is the heart of modern plastic manufacturing. Its ability to deliver precision, scalability, and cost-effectiveness has made it indispensable in multiple industries. With the adoption of advanced technologies like servo systems and automation, manufacturers are achieving faster production cycles and reduced operational costs.

By partnering with industry leaders like Daoben Machinery, businesses can access world-class injection molding solutions that are designed for efficiency, durability, and the future of manufacturing.